RGB LED Strip: A Practical, Real-World Installation Guide for Homeowners, Makers, and Pros

RGB LED Strip: A Practical, Real-World Installation Guide for Homeowners, Makers, and Pros

If you’ve searched for “rgb led strip,” you’re likely planning a lighting project and want clear, practical advice—not just specs and sales talk. This comprehensive guide distills real-world lessons from hundreds of installs into a step-by-step playbook you can actually use. You’ll learn how to plan your layout, pick the right strip and power supply, avoid color mismatches and voltage drop, integrate with smart homes, and troubleshoot flicker or dim colors after everything is mounted. Whether you’re lighting kitchen cabinets, a gaming desk, a retail shelf, a van, or a backyard pergola, this article will help you get professional results on the first try.

What Is an RGB LED Strip—and When It’s the Right Choice

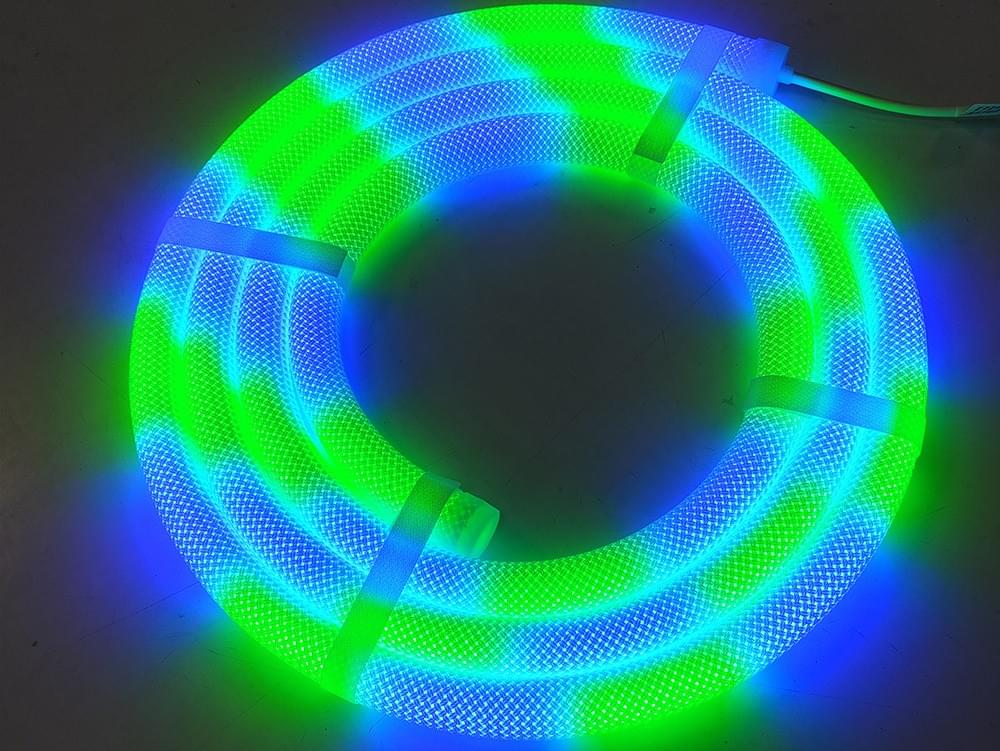

An rgb led strip is a flexible tape populated with tri-color LEDs (red, green, blue) that blend to produce millions of colors. It typically runs on low-voltage DC (12V or 24V), has adhesive backing, and can be cut at marked intervals. When is RGB the right fit?

- Mood and accent lighting where saturated colors matter.

- Event, stage, and set designs with dynamic color scenes.

- Retail displays and hospitality environments that change seasonally.

- PC builds, gaming rooms, streaming backgrounds, and content sets.

- Outdoor architectural features where color highlights are desired.

When CRI (color rendering index) for true-to-life whites is critical—e.g., food prep, makeup mirrors—consider RGBW or RGBCCT strips, which add dedicated white LEDs. But for most decorative applications, a high-quality rgb led strip yields excellent results.

Planning First: The Single Biggest Factor in a Clean Install

Before peeling the adhesive backing, write down:

1.Mounting location and total lengths (include verticals, returns, and around corners).

2.Power source location and the route for low-voltage cables.

3.Controller location and Wi-Fi/remote access needs.

4.Environment (dry, damp, wet) for choosing IP rating.

5.Profiles/diffusers to hide dots and improve heat dissipation.

6.Serviceability: can you replace a section without tearing apart cabinetry?

A quick sketch with measurements prevents 80% of common mistakes.

Measuring and Segmenting

- Measure the visible run length to the nearest cut-point. Common cut lengths: 25–100 mm depending on LED density and voltage.

- If the run exceeds the recommended single-feed length (for example, 5 m on 12V or 10 m on 24V for many mid-power strips), plan for power injection at both ends or midpoint.

- For corners, budget extra length for gentle bends or use corner connectors/soldered jumpers.

Choosing the Right RGB LED Strip

Not all rgb led strips are equal. Evaluate these specs first:

- Voltage: 12V vs 24V. 24V reduces current for the same power, lowering voltage drop on long runs. Choose 24V for runs over ~5 m where possible.

- LED density: 30/60/96/120 LEDs per meter. Higher density means smoother light and fewer visible “dots,” but more power and heat.

- Power draw: W/m. Typical RGB strips range from 7–20 W/m. High�output products can exceed 20 W/m.

- PCB copper weight: 2 oz copper handles current and heat better than 1 oz, reducing color shift across long runs.

- IP rating: IP20 (indoor), IP65 (splash�resistant), IP67/IP68 (outdoor/wet). Silicone or PU encapsulation affects diffusion and heat.

- Bin consistency: Choose brands with tight binning to prevent color variation between rolls.

- Adhesive: Genuine 3M VHB or equivalent resists peel in warm installations.

- Certifications and warranty: Look for UL/ETL/CE marks and realistic warranties (2–5 years) from reputable vendors.

RGB vs RGBW vs Addressable (Digital)

- RGB (4-wire, common anode) mixes red, green, blue. Best for broad color.

- RGBW adds a dedicated white channel, improving whites and pastels and increasing brightness in desaturated colors.

- Addressable RGB (aka “digital,” “individually addressable,” WS2812B/APA102/etc.) allows LED-by-LED control for effects, but requires special controllers and careful data-line integrity management. For architectural installs, analog RGB or RGBW remains simpler and more robust.

Power Calculations: The Non-Negotiable Step

Undersized power supplies cause dimming, color drift (white turns pink/teal), and controller resets. Here’s a quick method:

1.Determine total wattage: strip power (W/m) × total meters.

2.Add 20–30% headroom for efficiency and future expansion.

3.Match voltage exactly (12V strip → 12V supply; 24V → 24V).

4.Calculate current: I = P / V for wire sizing and controller channel limits.

Example: 10 meters of 14 W/m 24V RGB

- Total load: 140 W. Add 25% → 175 W.

- Choose a 24V, 200–240 W power supply.

- Current: 175 W / 24 V ≈ 7.3 A. Size wire and fuses accordingly.

Power Injection Strategy

Even with the right supply, voltage drop along the strip can cause the far end to look warmer or dimmer. Combat this by:

- Feeding from both ends of a run.

- Injecting power every 2.5–5 m depending on current draw and copper weight.

- Running home-run power cables from a distribution block to each injection point.

Wire Gauge, Connectors, and Soldering

For currents under ~3 A over short distances (<2 m), 20 AWG can suffice. For 5–10 A, jump to 18 AWG or 16 AWG, especially on longer cable runs.

Avoid clip-on pierce connectors for permanent installs; they often loosen and oxidize. Solder joints with heat-shrink tubing are far more reliable.

Observe polarity: RGB strips are typically common +V (anode), with separate R, G, B negatives.

Tip: Label cables at both ends. Future you will thank present you.

Controllers: Simplicity vs Flexibility

Your controller determines how you choose colors and scenes.

- Basic IR/RF remotes: Quick and cheap, no Wi-Fi needed. Line-of-sight for IR; RF has better range.

- Wi-Fi/BLE controllers: App control, scenes, schedules, voice assistants. Ensure the app is maintained and supports local control if you care about privacy and reliability.

- DMX/0–10V/DALI: For commercial or pro theatrical integration.

- Addressable pixel controllers: For WS281x or similar strips; plan power/data injection and level-shifting for long data lines.

Make sure the controller’s channel current ratings meet your load. Many small controllers are limited to 2–6 A per channel. For larger projects, use an RGB amplifier or a multi-channel constant-voltage LED driver.

Heat Management and Aluminum Profiles

Heat shortens LED lifespan and shifts color over time. Mount rgb led strip to an aluminum profile or at least a thermally conductive surface when power exceeds ~10 W/m or when the strip is encapsulated (IP65+). Benefits:

- Extends LED and adhesive life.

- Provides a clean, professional look with snap-in diffusers.

- Smooths out hotspots and reduces visible dotting.

Choose deep diffusers for dot-free lines of light, especially with low-density strips or when the diffuser is visible at eye level.

Surface Prep and Mounting

- Clean surfaces with isopropyl alcohol; let dry fully.

- Test-fit the entire run and power it on before committing the adhesive.

- Apply moderate, even pressure as you lay the strip; avoid stretching.

- For porous or rough surfaces, use mounting clips or an additional tape (e.g., 3M VHB) under the strip or profile.

- Keep a gentle bend radius; don’t crease the PCB.

IP Ratings and Outdoor Installs

For kitchens (under-cabinet near steam), bathrooms, or outdoor locations:

- Splash zones: IP65 with silicone sleeve or coating.

- Direct exposure/rain: IP67/IP68 with end-cap sealing and silicone potting.

- UV exposure: Look for UV-resistant jackets; some clear silicones yellow over time.

- Temperature swings: Provide expansion space; avoid hard 90° corners with encapsulated strips.

Always place the power supply in a dry, ventilated enclosure and follow local electrical codes.

Avoiding Common Color and Brightness Problems

Real-world issues typically trace back to power and signal integrity:

- Pinkish whites or shifting hues down the line: Voltage drop. Use thicker cable, 24V strips, and power injection.

- Flicker when dimming: Low-quality PWM or underpowered supply. Choose quality drivers/controllers with higher PWM frequency (≥1 kHz, ideally 2–8 kHz for cameras).

- Sections out or off-color: Cold solder joints, damaged segments from bending, or mismatched reels. Test each reel; don’t mix batches if color consistency matters.

- Controller reboots on bright white: Inrush or overcurrent. Upsize the power supply or add a soft-start/NTC thermistor; ensure adequate headroom.

RGB LED Strip in Specific Installations

UnderCabinet Kitchen Lighting

- Prefer RGBW for clean whites, but a high-quality rgb led strip can still work if color is the focus.

- Use aluminum profiles with opal diffusers to minimize dotting on counters.

- Hide the controller and power supply in an accessible cabinet; cut a slot for ventilation.

- Add a wall-mounted low-voltage switch or smart button for quick on/off independent of the app.

Cove Ceilings and Crown Molding

- Choose 24V for long runs and plan power injection every 5–10 m.

- Use high-density strips (≥60 LEDs/m) for even lines of light.

- Keep the strip 2–4 inches away from the reflecting surface to avoid scalloping.

- Consider a master controller with multiple amplifiers for a uniform look.

Gaming Desk, PC, and Studio Backgrounds

- Addressable strips excel here for animations and reactive effects.

- For camera work, use high-frequency PWM drivers to prevent banding.

- Diffusers and backlighting on walls (bias lighting) create depth without glare.

Stairs and Toe-Kicks

- Use rigid channels for protection; install motion sensors or step-triggered scenes.

- Keep wiring pathways safe from foot traffic; use low-profile aluminum extrusions.

Vehicles, Vans, and Boats

- Electrical noise and voltage variation are common. Use buck converters/regulators to provide a stable 12V/24V output to the rgb led strip.

- Fuse each branch close to the battery; use marine-grade tinned copper wire and heat-shrink terminals.

- Moisture protection is mandatory; choose IP67+ and seal end caps carefully.

Outdoor Pergolas and Soffits

- Choose weatherproof strips and UV-stable diffusers.

- Mount strips facing the structure (indirect) to avoid glare and improve perceived uniformity.

- Provide drip loops and weep holes in enclosures to manage condensation.

Smart Home Integration

- Wi-Fi controllers that support local protocols (e.g., MQTT) are more reliable than cloud-only solutions.

- For voice control, confirm compatibility with Google Assistant, Alexa, or Apple Home.

- Scene logic: Create warm, low-saturation evening scenes and vibrant daytime party scenes. Use schedules and sunrise/sunset automations.

- For pro systems (Control4, Crestron), use DMX decoders or dedicated constant-voltage drivers that integrate directly.

Dimming and PWM Considerations

Architectural comfort prefers flicker-free dimming. Look for controllers with high PWM frequency and sufficient bit depth (12–16 bit) for smooth fades.

When filming, test on camera at your shutter speeds. Increase PWM frequency or adjust camera settings to eliminate banding.

Cable Management and Aesthetics

Route wires along cabinet tops or behind trim. Use adhesive cable clips and paintable raceways for clean lines.

Keep low-voltage cables separate from mains to reduce interference and meet code.

Service loops: Leave a small loop near controllers and junctions for easier maintenance.

Safety, Code, and Reliability

Use UL-listed power supplies where required. Enclose supplies in ventilated metal boxes; never bury them in insulation.

Fuse each circuit appropriately. A simple inline mini-blade fuse at the distribution block can prevent melted wires.

Avoid daisy-chaining many reels end-to-end without power injection. Overheating pads and color drift are common failure modes.

Budgeting: Where to Spend and Where to Save

Spend on the strip and power supply. Cheap strips often have poor binning, thin copper, and weak adhesive.

Save with simpler controllers if you don’t need complex effects.

Invest in aluminum profiles and quality connectors; they make installs look professional and last longer.

Installation Workflow Checklist

1.Measure, sketch, and choose 12V or 24V.

2.Calculate power and current; choose a power supply with 20–30% headroom.

3.Decide controller type and location; confirm app/ecosystem compatibility.

4.Choose rgb led strip density, IP rating, and profile/diffuser.

5.Order extra length (10–15%) for mistakes and future repairs.

6.Bench test: Connect small segments, verify color order and brightness.

7.Prep surfaces; cut and dry-fit all segments, mark cut points.

8.Solder leads, test each segment, heat-shrink all joints.

9.Mount profiles, then the strip; power on and test in place.

10.Final cable dressing, labeling, and programming scenes.

Troubleshooting Guide

One color missing along a section: Open circuit on that color’s negative. Inspect solder pads and connectors; reflow the joint.

Entire strip dead, controller lit: Polarity reversed or blown inline fuse. Verify with a multimeter.

First few LEDs a different color (addressable only): Data integrity problem. Shorten data line, add a level shifter/terminating resistor, or reduce refresh rate.

Random resets at full white: Power supply is undersized or overheating. Upsize wattage, improve ventilation, or split loads across multiple supplies.

Adhesive failing: Surface contamination or heat. Clean with alcohol, add VHB tape, or use mounting clips within profiles.

Maintenance and Longevity

Dust and clean diffusers every few months; dust absorbs light and traps heat.

Avoid running maximum brightness white for extended periods unless the strip and profile are rated for it.

Keep spares from the same batch for future repairs to maintain color consistency.

Frequently Asked Questions About RGB LED Strip Installs

How many meters can I run from one end?

It depends on voltage and current. Many 12V strips look best under 5 m without injection; 24V can often go 7–10 m. Always check the datasheet.

Can I cut and rejoin strips?

Yes, at marked cut lines. Soldering is preferred for reliability; keep track of +V, R, G, B pads.

Do I need a resistor or driver?

Constant-voltage rgb led strips are designed for a regulated 12V or 24V supply and a controller that switches the negative channels. No external resistors are needed if you use the correct supply.

What’s better for long runs, 12V or 24V?

24V, because current is lower for the same power, reducing voltage drop and cable heating.

Will RGB make good white light?

It can, but RGBW or RGBCCT produces truer whites and adjustable color temperature.

Are addressable strips harder to install?

Yes. They require careful data wiring, proper power injection, and compatible controllers. The payoff is advanced effects.

Example Parts List for a Typical 24V RGB Cove Project

- 24V rgb led strip, 60–96 LEDs/m, ~12–16 W/m, 10–15 m total.

- 24V 240–320 W UL-listed power supply with 25% headroom.

- 4-channel Wi-Fi controller compatible with your smart home platform.

- Aluminum U-channel with opal diffuser, cut to lengths.

- 16–18 AWG stranded copper cable for injection runs.

- Inline mini-blade fuses and a small distribution block.

- Heat-shrink tubing, solder, flux, cable clips, and labels.

Final Thoughts: Get Pro Results With Careful Planning

The difference between a frustrating, flickery setup and a jaw-dropping installation usually comes down to planning and power delivery. Choose a quality rgb led strip with the right voltage and density, size your power supply with headroom, mount on aluminum for heat management, and inject power for long runs. Keep wiring neat, solder your joints, and test at each step before you seal things up. Follow these real-world practices and your rgb led strip project will look bright, even, and reliable for years to come.

If you want, share your specific measurements, environment (indoor/outdoor), and photos of the mounting area. I can calculate exact wattage, wire gauges, injection points, and a shopping list tailored to your project.