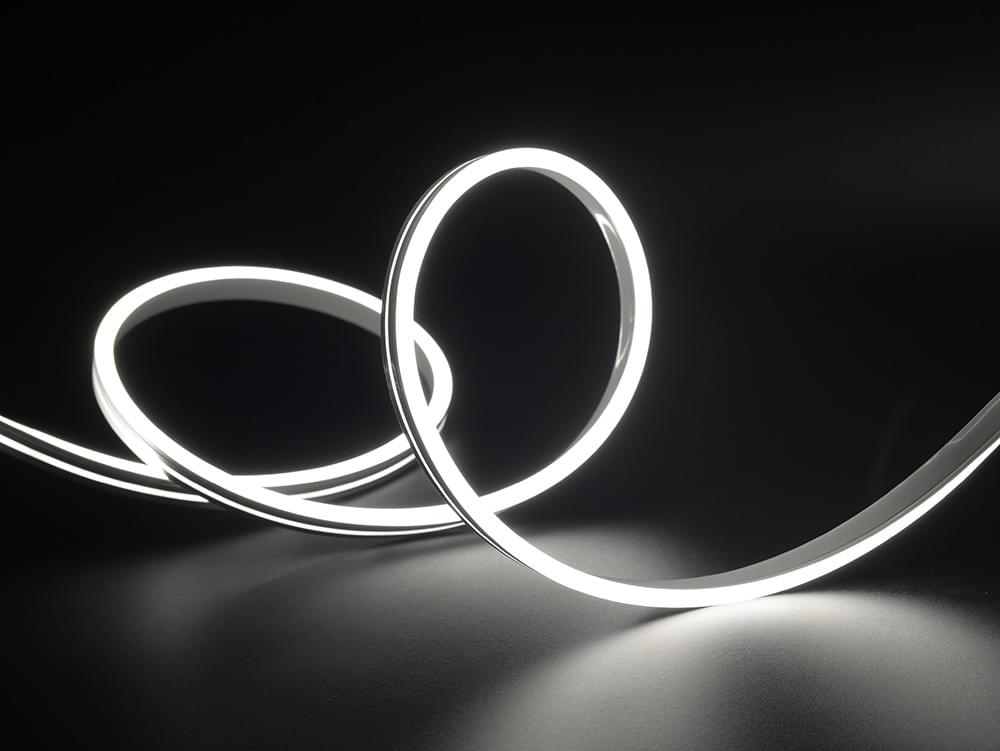

Neon LED Strip: Waterproof Performance and Ultra-Uniform Illumination

Neon LED Strip: Waterproof Performance and Ultra-Uniform Illumination

What Is a Neon LED Strip?

A neon LED strip is a flexible, encapsulated LED lighting product engineered to mimic the continuous glow of classic glass neon while using low-voltage, energy-efficient LEDs. Unlike conventional PCB LED tape that shows visible “hot spots,” a neon LED strip integrates:

- A dense LED array for high pixel count per meter

- A thick, optical-grade silicone or PVC jacket that acts as both diffuser and protective barrier

- A flexible internal structure (often a side-bend or top-bend design) enabling curves, shapes, and signage

The result is a dotless, uniform line of light suitable for indoor and outdoor use, signage, architectural accents, and wet locations—provided you choose the correct waterproof rating.

Why Waterproof Performance Matters for Neon LED Strips

Water is the most common environmental threat to LED lighting. Moisture intrusion can cause:

- Corrosion of copper pads and solder joints

- Short circuits between positive/negative rails

- Electrochemical migration (ECM) and dendrite formation

- Premature lumen depreciation due to trapped humidity and thermal stress

- Optical haze or yellowing inside inferior jackets

Neon LED strips address these risks using continuous encapsulation and precise end-cap sealing, providing robust barriers against dust, spray, rain, and even submersion, depending on the IP rating.

Understanding IP Ratings (IP65, IP67, IP68) for Neon LED Strips

IP (Ingress Protection) ratings define how well an enclosure resists solids and liquids.

- First digit (solids): 0–6. “6” means dust-tight.

- Second digit (liquids): 0–9K. Higher numbers indicate stronger water resistance.

Common IP levels for neon LED strips:

- IP65: Dust-tight; protected against water jets from a nozzle. Suitable for kitchens, covered patios, and splash zones—not for prolonged exposure or immersion.

- IP67: Dust-tight; protected against temporary immersion (typically up to 30 minutes at ≤1 m). Ideal for outdoor façades, signage in the rain, and areas that occasionally flood.

- IP68: Dust-tight; protected for continuous immersion under conditions specified by the manufacturer (often >1 m). Best for fountains, pool perimeters above the waterline with splash, marine signage, or installations where standing water is expected. Always confirm exact depth/time specs.

Key takeaway: Match IP rating to the real environment and installation method. Waterproofing is only as good as the weakest link—often the end caps, cable glands, and field connections.

How Neon LED Strips Achieve Waterproofing

Waterproof performance is a system, not a single material. High-quality neon LED strips combine:

Continuous Encapsulation

- Optical silicone or UV-stabilized PVC fully surrounds the LED and PCB, leaving no exposed copper.

- Extruded in one piece to minimize seam lines; some premium models use co-extrusion for a dual-hardness structure: a rigid core for dimensional stability and a soft outer layer for sealing and light diffusion.

End Cap Sealing

- Purpose-made end caps (often molded silicone) are bonded with compatible adhesives (e.g., RTV silicone).

- Correct primer and adhesive chemistry ensure covalent bonding rather than mere surface adhesion.

Cable Entry and Glands

- Cable glands compress around the jacket for strain relief and water blocking.

- Potted connectors with epoxy or silicone prevent wicking of water along conductors.

Potting and Fillers

- In high-IP strips, internal voids are eliminated using potting compounds that resist thermal cycling and hydrolysis.

UV and Chemical Resistance

- Outdoor formulas include UV inhibitors and anti-yellowing stabilizers; marine applications may need salt-mist resistance.

- Oils and cleaning agents (common in kitchens and retail) require solvent-resistant jackets.

Thermal Design

- Waterproof jackets can trap heat. Premium strips use thermally conductive pathways (copper mass, aluminum channels) to dissipate heat while keeping water out.

Uniform Illumination: Why Neon LED Strips Look “Dotless”

“Uniform light” is the defining advantage of neon LED strips. The smooth glow results from four design pillars:

High LED Density

- More LEDs per meter reduce spacing between diodes, minimizing shadow and brightness valleys.

- Pair with constant-current architectures to equalize output across long runs.

Optical-Grade Diffusion

- Silicone/PVC diffusers with precise translucency scatter point sources into a continuous line.

- Micro textured inner surfaces break up residual hot spots without sacrificing efficiency.

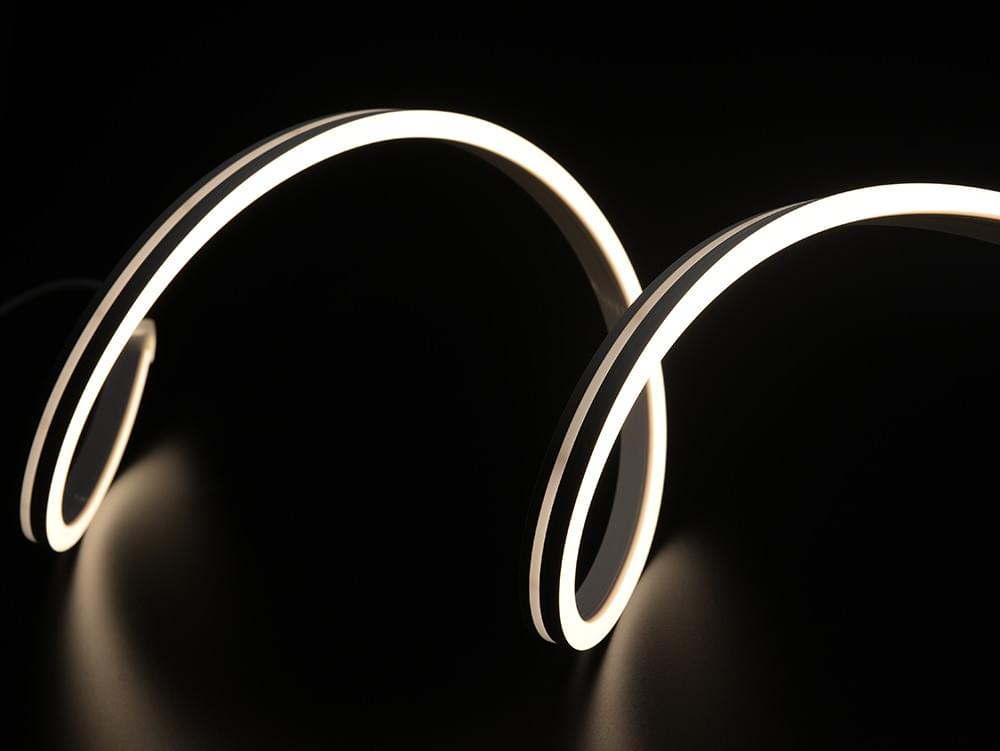

Geometric Light Path

- Top bend and side bend profiles direct light where you need it.

- Internal reflectors and white PCB solder masks enhance mixing before light exits.

Tight Binning and CRI Management

- LEDs sorted by color temperature (CCT) and forward voltage maintain chromatic uniformity along the entire length.

- High CRI (≥90) options render colors accurately while keeping tone consistent end to end.

Compared to bare LED tape with clip-on diffusers, a neon LED strip integrates diffusion and mechanics from the start, producing superior uniformity for façades, coves, and signage without visible dots—even at close viewing distances.

Waterproof vs. Light Uniformity: Do You Have to Compromise?

Not with the right product. Older designs sometimes sacrificed brightness or introduced color shift because thick jackets absorbed light. Modern neon LED strips use:

- High transmittance silicone (over 90% visible light transmission)

- Surface micro optics that diffuse without absorbing as much flux

- Efficient mid power LEDs and improved drive electronics to offset any losses

The result: IP67–IP68 waterproofing with a continuous, evenly lit appearance, suitable for high end architectural lines of light.

Where Waterproof, Uniform Neon LED Strips Excel

- Outdoor architectural outlines: parapets, cornices, and façade accents

- Wayfinding and safety: stair nosings, handrails, ramp edges (with proper profiles and glare control)

- Hospitality and retail: weather-exposed patios, signage, brand color lines

- Bathrooms and spas: showers, steam rooms, and vanity halo lighting (confirm local electrical code and GFCI requirements)

- Kitchens and bars: under-bar kicks, backsplashes, and toe-kicks resistant to spills and cleaning agents

- Marine and docks: decorative rails, transom logos, and pathway lighting (verify salt-spray suitability)

- Event and stage: durable, transportable lines of light with dotless, camera-friendly output

Choosing the Right IP Rating for Your Project

Match the environment, not just the marketing:

- Indoor dry (accent): IP40–IP54 is enough—but many still pick IP65 for robustness.

- Indoor wet (bath/shower): IP65 minimum; IP67 preferred, with sealed junctions.

- Outdoor exposed (rain, snow, UV): IP67 with UV-stable jacket; consider IP68 for snowmelt drains or areas with standing water.

- Near pools/fountains: IP68; verify depth rating, chlorine resistance, and temperature cycles.

- Marine/salt: IP67–IP68 with salt-mist certification and marine-grade connectors.

Remember: electrical codes may restrict low-voltage lighting within certain pool zones. Always follow local regulations and use GFCI-protected circuits.

Material Science: Silicone vs. PVC Jackets

Silicone Advantages

- Excellent UV stability and anti-yellowing

- Wider temperature range (often −20°C to +50°C or greater)

- Better chemical resistance to many cleaners and salts

- Softer feel, tighter bend radius without cracking

Silicone Considerations

- Can be more expensive

- Requires compatible adhesives; some silicones resist standard glues

PVC Advantages

- Cost-effective and mechanically robust

- Good diffusion when formulated correctly

- Wide profile and color options

PVC Considerations

- Potential for yellowing over long UV exposure unless stabilized

- Stiffer in cold climates; larger minimum bend radius

For premium outdoor uniformity and long life, silicone neon LED strips are often preferred. For budget-sensitive or indoor installations, PVC can perform well if UV exposure is minimal.

Thermal Management in Waterproof Neon Strips

Waterproofing can trap heat. Excess heat reduces LED lifetime and causes color drift. Mitigation strategies:

- Use aluminum mounting channels as heat spreaders

- Keep drive current within manufacturer limits; avoid over-driving for incremental brightness gains

- Allow ventilation behind profiles when possible

- Choose constant-current designs that maintain consistent current as voltage varies, preventing hot spots

A cooler strip maintains uniform light and prevents localized dimming, especially on long runs.

Powering for Uniform Brightness Across Long Runs

Voltage drop is the enemy of uniformity. As current flows down a strip, resistance causes voltage to fall, dimming the far end. Best practices:

- Use 24 V or 48 V systems for long runs; higher voltage reduces current and voltage drop

- Power from both ends or from the center of the run

- Use thicker gauge supply cable (lower AWG) for longer distances

- Select constant-current neon strips or those with segment-level regulation

- Respect maximum run lengths specified by the manufacturer

Combine proper power design with high-quality LEDs and diffusion to preserve uniform brightness outdoors.

Installation Techniques That Preserve Waterproofing

Even the best neon LED strip can fail if field connections are sloppy. Follow these steps:

Measure Twice, Cut Once

- Cut only at marked cut points to maintain sealed circuit integrity.

Use Approved End Caps and Adhesives

- Clean surfaces with isopropyl alcohol.

- Apply manufacturer-approved primer and RTV silicone; allow full cure time (often 24 hours) before stressing the joint.

Seal Cable Entries

- Use compression glands or pre-molded pigtails.

- Pot any exposed conductors with neutral-cure silicone.

Manage Bends

- Respect minimum bend radius; avoid twisting top-bend strips in the side-bend plane.

- For tight curves, choose side-bend neon profiles designed for signage.

Mounting

- Use stainless-steel clips or aluminum channels for straight lines.

- On porous masonry outdoors, add a thin bead of compatible sealant behind the channel to prevent water accumulation.

Drainage and Expansion

- Provide weep paths so water cannot pool around end caps.

- Leave thermal expansion gaps per datasheet to avoid jacket stress in heat/cold cycles.

Electrical Safety

- Keep drivers in dry, ventilated enclosures rated for the environment (e.g., IP65+ outdoors).

- Use GFCI where required; follow local codes for wet zones.

How to Verify Waterproof Claims: Practical Tests

If you’re comparing brands, ask about or perform:

Immersion Test (for IP67/IP68)

Submerge a finished assembly—including end caps and connectors—for the time/depth stated. Inspect for bubbles, fogging, or moisture ingress.

Spray/Jet Test (for IP65)

Use a directional water jet for several minutes. Check for water beads under the jacket.

Thermal Cycling

Cycle from hot to cold (e.g., +50°C to −20°C) while damp. Look for micro-cracks and seal integrity failures.

Salt-Mist/UV Exposure

For coastal use, request test reports showing resistance to salt corrosion and UV aging (e.g., 500–1000 hours accelerated).

Continuity and Insulation Resistance

After tests, measure insulation resistance between positive/negative and jacket. A drop indicates moisture ingress.

Credible suppliers can provide third-party test data and detailed assembly instructions.

Color Quality and Uniformity: CCT, CRI, and R9

Uniform brightness is only part of the story—color uniformity matters too:

CCT Options

2200K–2700K: Warm, hospitality ambiance

3000K–3500K: Neutral warm for residential/commercial

4000K–5000K: Clean white for retail and outdoors

RGB/RGBW/RGBA: Dynamic accents and signage

CRI and R9

Aim for CRI ≥90 with R9 ≥50 for rich reds and natural skin tones.

Tight binning (≤3-step MacAdam) maintains consistent tone along long façades.

Dimming

PWM or 0–10V drivers should maintain flicker-free performance at low dimming levels.

For video/photo, consider high-frequency PWM or constant-current dimming to avoid banding.

Durability Beyond Water: UV, Abrasion, and Chemicals

Outdoor neon LED strips face more than rain:

- UV Exposure: Choose UV-stabilized silicone to resist yellowing and haze.

- Abrasion: Select profiles with harder outer layers or protective channels where physical contact is likely.

- Chemicals: Bars, kitchens, pools, and spas involve cleaners and chlorides; confirm chemical resistance compatibility.

- Impact: For public spaces, look for IK impact ratings or mount behind protective trims.

A strip that resists these stresses retains both waterproofing and uniform glow over years.

Energy Efficiency and Sustainability

Modern neon LED strips deliver high efficacy with visual comfort:

- Efficacy: 70–100+ lm/W even with diffusion, depending on CCT and profile

- Dimming: Reduces energy in low-light conditions without changing color temperature on single-CCT models

- Longevity: 30,000–50,000+ hours L70 when properly cooled and powered

- Maintainability: Field-replaceable segments and standardized drivers minimize waste

Selecting efficient drivers and proper controls further reduces energy while keeping that continuous neon look.

Common Mistakes to Avoid

- Choosing IP65 for a site with standing water or frequent pressure washing

- Cutting off factory-molded pigtails and using unapproved connectors

- Ignoring voltage drop on long runs, leading to visible dimming

- Bending beyond the rated radius or twisting the profile, creating micro-cracks

- Using indoor drivers outdoors without weatherproof enclosures

- Mounting in troughs where water pools around end caps

A little planning preserves both waterproofing and light uniformity.

Buying Checklist for a Waterproof, Uniform Neon LED Strip

- IP rating suited to your environment (IP67/IP68 for wet/outdoor)

- Verified test data for immersion, UV, and thermal cycling

- Optical-grade silicone jacket with anti-yellowing additives

- LED density and diffusion designed for dotless output at your viewing distance

- Tight LED binning (CCT and forward voltage) for color consistency

- Clear maximum run length and wiring diagrams for uniform brightness

- Compatible end caps, glands, and approved adhesives included

- High-quality, dimmable driver options (PWM, 0–10V, DALI, or DMX for RGB/RGBW)

- Aluminum channels or heat-spreading accessories available

- Warranty terms that cover outdoor use

Installation Example: Outdoor Façade Line of Light

Scenario: 30 meters of continuous white neon outline on a storefront canopy, exposed to rain and sun.

- Product: 24 V silicone top-bend neon, IP67, 4000K, CRI 90

- Layout: Three runs of 10 m each, powered from both ends

- Power: 24 V constant-voltage drivers in IP65 enclosures, each on a dedicated circuit with GFCI

- Mounting: Aluminum channels every 0.5 m, sealed with compatible silicone behind channels where they contact porous masonry

- Sealing: Factory-molded pigtails; field end caps bonded with primer + RTV silicone; cured 24 hours before energizing

- Result: Dotless, uniform glow with no visible dimming across the canopy, stable in heavy rain

Installation Example: Spa and Shower Accent

Scenario: Warm backlighting around a steam shower niche and bench.

- Product: 24 V silicone neon, IP67 (or IP68 if direct water flow is continuous), 2700K

- Safety: Low-voltage circuit with GFCI protection; driver in a dry, accessible location outside wet zone

- Powering: Short runs ≤5 m, powered from one end; 16–18 AWG feed; all terminations potted/sealed

- Mounting: Non-corrosive clips on sealed tile; avoid water traps around end caps

- Result: Soft, uniform illumination resilient to moisture and cleaning agents

FAQs About Neon LED Strips

Are neon LED strips waterproof?

Many are. Look for IP65 (splash-proof), IP67 (temporary immersion), or IP68 (continuous immersion as specified). For rain-exposed or wet locations, IP67 or higher is recommended.

What’s the difference between a neon LED strip and regular LED tape?

Neon strips encapsulate LEDs in a thick diffuser for dotless, uniform light and higher environmental protection. Standard tapes often show LED dots and need separate channels or covers.

Can I use neon LED strips outdoors year round?

Yes, with IP67+ and UV-stable materials. Ensure proper sealing, UV resistance, and drivers rated for outdoor use.

How do I get a continuous, uniform glow without hot spots?

Choose neon strips with high LED density, optical-grade silicone diffusion, and proper power design (higher voltage, dual-end feeds, or constant-current regulation).

Which IP rating do I need for a pool area?

Typically IP68, but confirm depth, chemical exposure, and local codes. Drivers must be located in dry, protected areas.

Do neon LED strips dim smoothly?

Yes. Use compatible dimmable drivers (PWM, 0–10V, DALI). For filming, pick high-frequency PWM or constant-current dimming to avoid flicker.

How long do neon LED strips last?

With correct installation and thermal management, expect 30,000–50,000+ hours to L70. Heat and moisture mismanagement shorten lifespan.

Can I cut and reconnect neon LED strips?

Only at marked cut points. Use manufacturer-approved connectors, glands, and adhesives to maintain waterproof integrity.

What’s better for outdoors: silicone or PVC neon?

Silicone generally offers superior UV stability and flexibility. PVC can be cost-effective indoors or in shaded exteriors with proper stabilization.

How do I prevent dimming at the end of long runs?

Use 24 V or 48 V versions, power both ends, keep within max run length, and choose properly sized feed cables.

Conclusion

A high-quality neon LED strip combines two essential strengths: reliable waterproof performance and ultra-uniform, dotless illumination. By understanding IP ratings (IP65 vs. IP67 vs. IP68), choosing UV-stable materials like optical-grade silicone, and following best practices for power distribution and sealing, you can achieve long-lasting lines of light in the harshest environments—without sacrificing the smooth, continuous glow that defines modern neon aesthetics.

Whether you’re outlining a storefront in heavy rain, accenting a spa shower with warm ambience, or shaping complex signage curves, the right neon LED strip will deliver consistent brightness, accurate color, and long-term durability. Match the product to the application, respect installation details, and verify waterproof claims with real testing—and your project will shine, season after season.